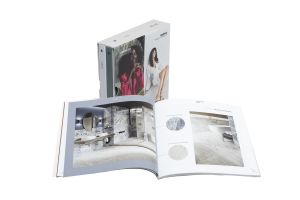

Custom Packaging – Prestigious Box Packaging for Your Brand

Exclusive branded packaging is more than just product protection—it’s an effective promotional tool. With unique designs and high-quality materials, our packaging solutions strengthen brand identity and enhance customer loyalty.

The premium packaging offered by Achilles combines the highest-quality materials, modern design, and a tailored approach to every order. We create custom packaging that becomes an integral part of your company’s visual identity, emphasizing its uniqueness. With a wide range of shapes, sizes, and finishing techniques, each rigid box stands out with its distinctive style and precise craftsmanship.

Choose Custom Rigid Boxes and Elevate Your Product!

Your packaging is the first thing a customer sees. That’s why investing in custom rigid boxes that fully reflect your brand’s identity is essential.

Ordering rigid boxes packaging from Achilles means:

- Complete customization – tailor the shape, color, and print of your rigid box packaging to align with your brand identity.

- Professional presentation – branded packaging enhances the quality and exclusivity of your product offering.

- Effective advertising – custom rigid box designs with logos boost brand recognition and visibility.

- Perfect fit – available in various formats, such as rigid gift box designs with lids, ensuring both aesthetics and product protection.

- Flexible production – choose materials, finishes, and printing techniques to create luxury rigid boxes that meet your needs.

ID: 79

Rigid Packaging Boxes – Customization Options & Box Types

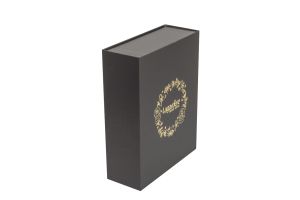

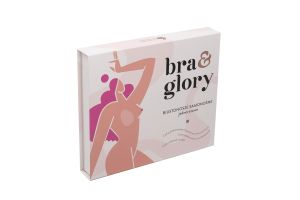

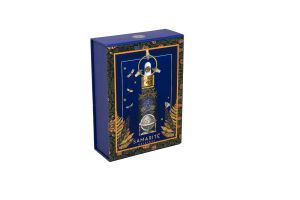

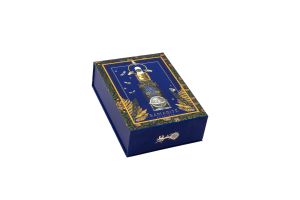

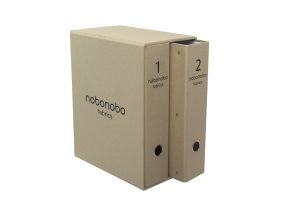

Rigid Boxes with Lids

Two-piece rigid packaging boxes with lids are a classic packaging solution made from high-quality rigid board. We offer a wide selection of premium finishes, including eco-friendly, linen-like, and printed options, with additional customization features such as embossing, hot stamping, and UV printing. These techniques add a luxury rigid boxes feel with an exclusive finish.

Upon request, the interior of the rigid gift box can include cardboard or foam inserts to showcase the product while offering extra protection. Our custom rigid boxes with logos allow for full personalization to match your brand’s visual identity.

✔ Perfect for: jewelry, luxury cosmetics, premium gift sets, high-end products.

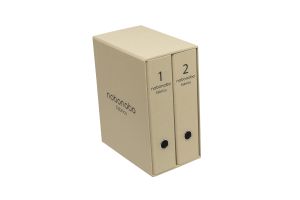

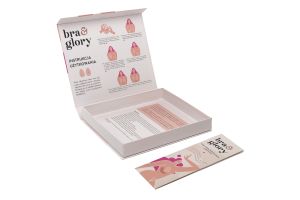

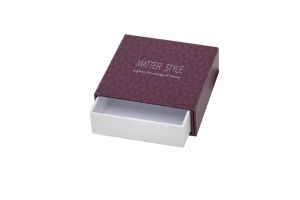

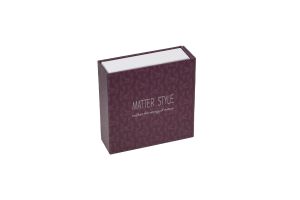

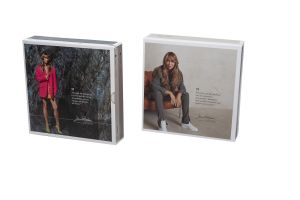

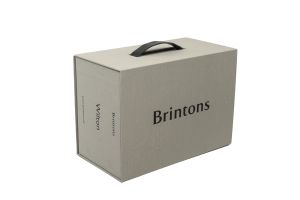

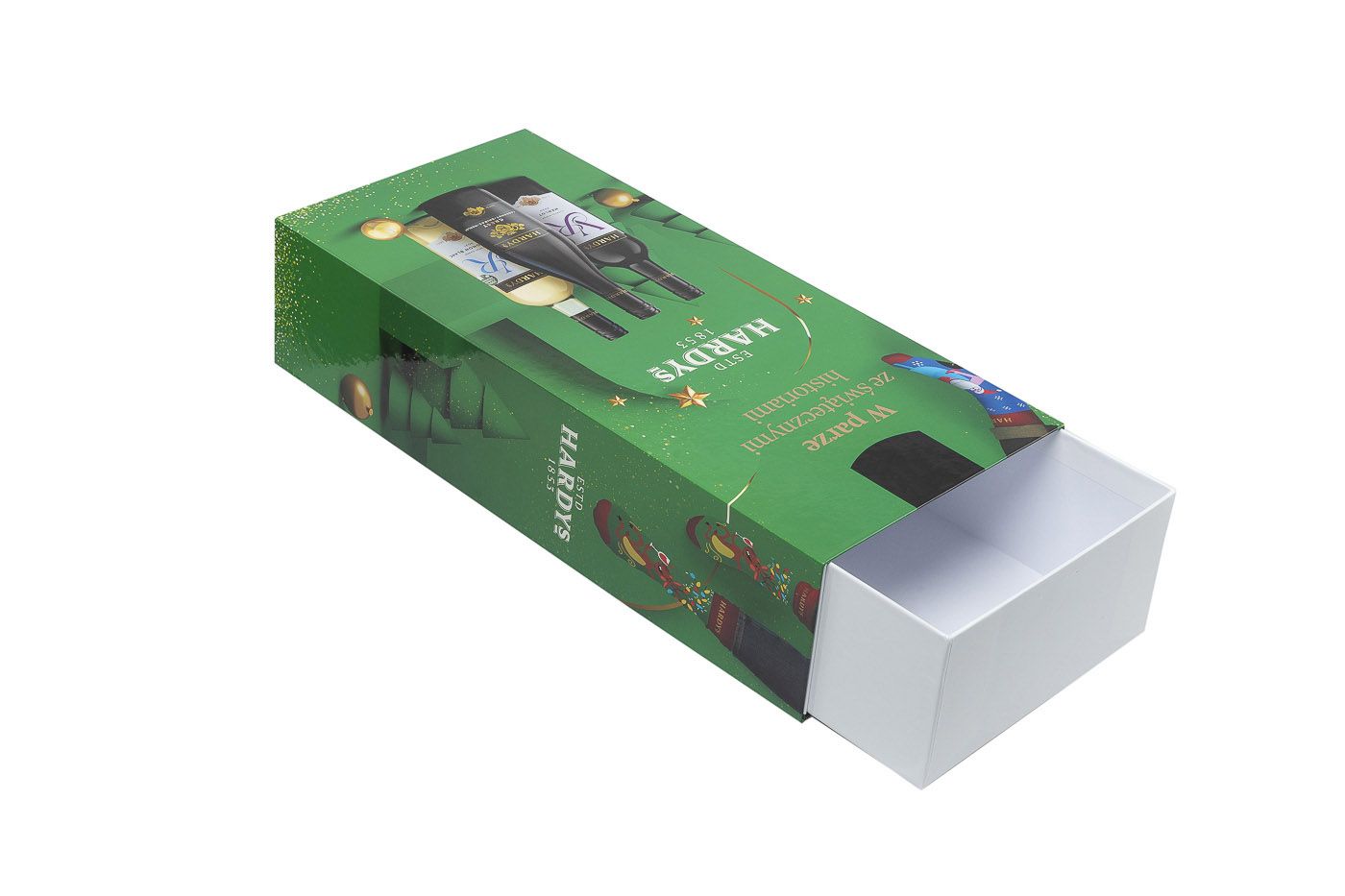

Slip Boxes

Our custom rigid box with a sliding drawer (slip box) is an excellent choice for brands seeking both originality and practicality. Made entirely from eco-friendly materials, these rigid packaging boxes offer a seamless opening experience while maintaining a premium look.

They can serve as branded packaging for promotional gift sets, adding a luxurious touch. The interior can also be lined with velvet, satin, or other premium box packaging materials to enhance elegance.

✔ Perfect for: premium electronics, high-end gadgets, limited edition products, corporate gifts.

ID: 43

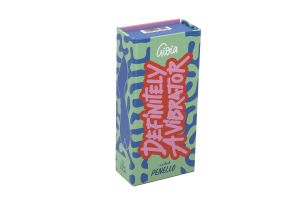

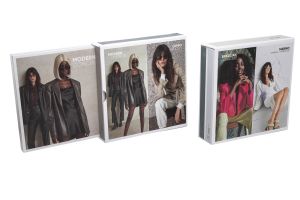

Personalized Rigid Box Packaging – Enhance Your Brand

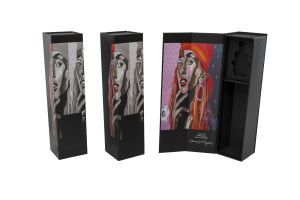

We offer custom rigid boxes with logos, fully tailored to match your brand identity. Customization options include:

- Premium embellishments – hot stamping, embossing, and metallic foiling.

- Printed rigid boxes – high-quality printing ensures perfect reproduction of logos and graphics.

- Exclusive finishes – velvet, soft-touch, lacquered, matte, or glossy coatings to create a distinctive look.

- Unique shapes and sizes – we develop custom projects to make your rigid box packaging one-of-a-kind.

Premium Rigid Boxes from a Trusted Manufacturer

As a leading rigid box packaging manufacturer, we use advanced production lines from renowned brands like Horauf, Ruggero Peroni, and CMC. Our modern technology allows us to produce both large-scale orders and small, customized batches, ensuring flexibility and precision in every project.

Our custom rigid boxes are crafted from top-quality rigid board, finished with a grooving technique that enhances their aesthetic appeal and durability. Every premium packaging project is designed with meticulous attention to detail, ensuring consistency and functionality at the highest level.

Eco-Friendly Luxury Rigid Boxes – Sustainability Meets Elegance

Our production process follows sustainable practices using renewable energy. We source FSC-certified materials and eco-friendly inks and adhesives. Our premium box packaging can be fully biodegradable, blending elegance with environmental responsibility.

By integrating eco-conscious technology, we offer custom packaging that meets the highest sustainability standards.

Order Custom Rigid Boxes with Logo – Contact Us Today!

Whether you need custom rigid box packaging, personalized box packaging, or luxury rigid boxes for premium products, our solutions are designed to exceed your expectations.

Every packaging project is created with uniqueness in mind, ensuring a sophisticated and lasting impression.

Contact us today to order personalized rigid packaging boxes tailored to your brand!

Accessories and refinements

To enrich our offer, we propose a wide range of accessories for our products, including various types of ring and lever mechanisms. Additionally, there is a possibility of personalization by painting in any color from the RAL palette or using mechanisms with a plastic, colored base. The offer of mechanisms also includes clips with teeth, clips with a pen holder and clamps for ring mechanisms.On request, our products can be subjected to additional refinement processes, such as calendering, selective UV varnishing, embossing, hot-stamping or application of structural foil. These effects not only improve the aesthetics of the products, but also provide additional protection against damage and dirt.

High quality as standard

FSC®, PEFC certified raw materials Ethics and ecology are the foundations that constitute MILO's mission and values. For years, we have been proudly powering our production with green energy and using only certified raw materials.

FSC®, PEFC certified raw materials Ethics and ecology are the foundations that constitute MILO's mission and values. For years, we have been proudly powering our production with green energy and using only certified raw materials.  Modern production line To ensure the highest quality, we work on industry-recognized production machines and systematically develop our technological capabilities. A team of competent Customer Advisors and a Prototype Studio are waiting for our partners.

Modern production line To ensure the highest quality, we work on industry-recognized production machines and systematically develop our technological capabilities. A team of competent Customer Advisors and a Prototype Studio are waiting for our partners.  Quality guarantee Each of our products is covered by a 12-month guarantee. We ensure repeatability and high quality of our products, offering innovative solutions at competitive prices.

Quality guarantee Each of our products is covered by a 12-month guarantee. We ensure repeatability and high quality of our products, offering innovative solutions at competitive prices.  Fast order fulfillment Our headquarters and production plant are located in Dobrzykowice, near Wrocław. Thanks to on-site production, we are able to significantly shorten the waiting time for an order.

Fast order fulfillment Our headquarters and production plant are located in Dobrzykowice, near Wrocław. Thanks to on-site production, we are able to significantly shorten the waiting time for an order. Frequently Asked Questions